- Home

- Products

- Ring Series

- Master Link Assembly

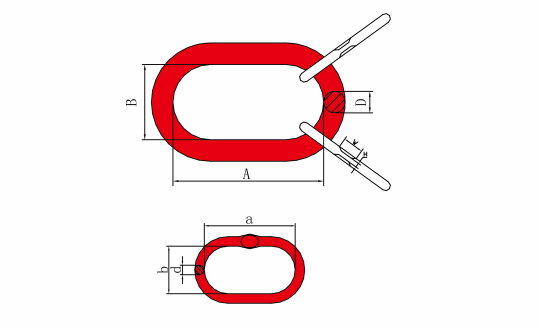

Master Link Assembly

Description

Master link assembly mainly used as a connection tool in lifting operations. Mainly used for assembling slings, sub-rings connected with double buckles and chain connections, assembled into synthetic rigging, used for lifting heavy objects and equipment, etc. It can be used in machinery, metallurgy, electricity, railway, water conservancy, ports, docks, papermaking Chemical industry.

Application:

Nuclear power, hydro-power, wind power, machine tools, shipbuilding, mining, marine engineering, heavy industry machinery, transportation, port and docks, metallurgy, bridges, aerospace ect.

Advantages:

1. The product has passed the environmental management system certification

2. Can apply for the certification of CCS, LR, DNV and other well-known classification societies

3. High product strength, light weight, exquisite design, strong versatility

4. Versatile functions, convenient use and safety testing

5. ODM, OEM service is available

Details specification:

- A-345 master link assembly

- A-346 master link assembly

- A-347 master link assembly

A-345 master link assembly (master link forging)

Specifications: 3 / 4,7 / 8,1,1-1 / 4,1-1 / 2,1-3 / 4,2,2-1 / 4,2-1 / 2,2-3 / 4, 3.

| A-345 master link assembly breaking load (4XWLL) | ||||||||

| specification | Inside length | Inside width | diameter | WLL (T) | Weight (KG) | |||

| 3/4 | 140 | 85 | 70 | 40 | 20 | 14 | 4.2 | 1.67 |

| 7/8 | 160 | 85 | 95 | 40 | 22 | 14 | 5.3 | 2.2 |

| 1 | 178 | 100 | 89 | 60 | 25 | 18 | 8 | 3.29 |

| 1-1/4 | 220 | 100 | 110 | 60 | 32 | 22 | 14 | 6.3 |

| 1-1/2 | 267 | 180 | 135 | 100 | 38 | 30 | 21.2 | 13.7 |

| 1-3/4 | 305 | 180 | 152 | 100 | 45 | 32 | 30 | 21.25 |

| 2 | 356 | 180 | 178 | 100 | 50 | 38 | 39.4 | 30.34 |

| 2-1/4 | 406 | 180 | 203 | 100 | 57 | 45 | 45 | 39.87 |

| 2-1/2 | 406 | 355 | 203 | 178 | 64 | 50 | 55.5 | 64.4 |

| 2-3/4 | 406 | 406 | 241 | 203 | 70 | 57 | 63 | 89 |

| 3 | 457 | 406 | 228 | 203 | 76 | 64 | 70 | 112.14 |

A-346 master link assembly (master link forging)

Specifications: 6-8, 7-8, 8-8, 10-8, 13-8, 16-8, 20-8, 22-8, 26-8, 32-8.

| A-346 master link assembly breaking load (4XWLL) | ||||||||

| specification | Inside length | Inside width | diameter | WLL (T) | Weight(KG) | |||

| 6-8 | 135 | 54 | 75 | 25 | 18 | 14 | 2.36 | 1.18 |

| 7-8 | 135 | 60 | 75 | 38 | 18 | 13 | 3.15 | 1.24 |

| 8-8 | 160 | 70 | 90 | 34 | 22 | 16 | 5.3 | 2.2 |

| 10-8 | 180 | 85 | 100 | 40 | 26 | 18 | 6.7 | 3.21 |

| 13-8 | 200 | 115 | 110 | 50 | 32 | 22 | 11.2 | 6 |

| 16-8 | 260 | 140 | 140 | 65 | 36 | 25 | 17 | 9.96 |

| 18-8 | 340 | 180 | 180 | 110 | 45 | 32 | 21.2 | 20 |

| 20-8 | 350 | 180 | 190 | 110 | 50 | 32 | 31.5 | 24 |

| 22-8 | 400 | 300 | 200 | 160 | 56 | 40 | 40 | 41.4 |

| 26-8 | 430 | 340 | 220 | 180 | 63 | 45 | 50 | 57.6 |

| 32-8 | 460 | 350 | 250 | 190 | 72 | 50 | 63 | 79 |

A-347 master link assembly (welded)

Specifications: 1/2, 11/16, 3/4, 7/8, 1-1 / 8, 1-1 / 4, 1-1-2, 1-3 / 4, 2.

| A-347 master link assembly breaking load (4XWLL) | ||||||||

| specification | Inside length | Inside width | diameter | WLL (T) | Weight (KG) | |||

| 1/2 | 100 | 85 | 60 | 40 | 14 | 12 | 2.40 | 0.83 |

| 11/16 | 160 | 100 | 90 | 60 | 18 | 14 | 3.20 | 1.76 |

| 3/4 | 160 | 100 | 90 | 60 | 20 | 14 | 5.00 | 1.96 |

| 7/8 | 180 | 150 | 100 | 70 | 22 | 18 | 8.00 | 3.25 |

| 1-1/8 | 270 | 160 | 140 | 90 | 28 | 22 | 12.00 | 6.74 |

| 1-1/4 | 270 | 180 | 140 | 100 | 32 | 25 | 17.40 | 9.31 |

| 1-1/2 | 300 | 270 | 160 | 140 | 40 | 32 | 21.00 | 19.1 |

| 1-3/4 | 340 | 285 | 180 | 155 | 45 | 36 | 30.00 | 26.6 |

| 2 | 350 | 340 | 190 | 180 | 50 | 45 | 40.00 | 42.9 |

- Lamb master link assembly

- 8006 master link assembly

- 8007 master link assembly

Lamb master link assembly

Specifications: MA16, MA20, MA22, MA25, MA28, MA32, MA38, MA45, MA23, MA24, MA50, MA60, MA70.

| Lamb master link assembly breaking load (4XWLL) | ||||||||

| specification | Inside length | Inside width | diameter | WLL (T) | Weight (KG) | |||

| MA16 | 120 | 86 | 70 | 51 | 16 | 14 | 3.8 | 1.2 |

| MA20 | 170 | 120 | 90 | 70 | 20 | 16 | 5.8 | 2.5 |

| MA22 | 170 | 150 | 90 | 80 | 22 | 20 | 7.6 | 3.8 |

| MA25 | 190 | 150 | 100 | 80 | 25 | 20 | 10 | 4.5 |

| MA28 | 210 | 170 | 110 | 90 | 28 | 22 | 12.7 | 6.4 |

| MA32 | 270 | 180 | 140 | 100 | 32 | 25 | 15.2 | 9.9 |

| MA38 | 270 | 270 | 140 | 140 | 38 | 32 | 25 | 18.2 |

| MA45 | 320 | 270 | 170 | 140 | 45 | 38 | 34 | 26.8 |

| MA23 | 270 | 150 | 140 | 75 | 22 | 16 | 5.8 | 3.67 |

| MA24 | 270 | 140 | 140 | 70 | 28 | 20 | 11.8 | 5.88 |

| MA50 | 380 | 270 | 200 | 140 | 50 | 38 | 40 | 33.2 |

| MA60 | 430 | 380 | 220 | 220 | 60 | 50 | 58 | 66 |

| MA70 | 500 | 430 | 250 | 220 | 70 | 60 | 84 | 103 |

8006 master link assembly

Specifications: 7 / 8-8, 10-8, 13-8, 16-8, 18 / 20-8.

| 8006 master link assembly breaking load (4XWLL) | ||||||||

| specification | Inside length | Inside width | diameter | WLL (T) | Weight (KG) | |||

| 7/8-8 | 160 | 60 | 90 | 35 | 20 | 14 | 4.6 | 1.7 |

| 10-8 | 180 | 80 | 100 | 40 | 25 | 16 | 7.8 | 2.95 |

| 13-8 | 240 | 90 | 140 | 50 | 32 | 22 | 14 | 6.5 |

| 16-8 | 270 | 180 | 140 | 100 | 40 | 28 | 24.8 | 11.6 |

| 18/20-8 | 300 | 180 | 155 | 100 | 45 | 32 | 33.3 | 18.65 |

8007 master link assembly

Specifications: 7 / 8-8, 10-8, 13-8, 16-8, 18 / 20-8.

| 8007master link assembly breaking load (4XWLL) | ||||||||

| specification | Inside length | Inside width | diameter | WLL (T) | Weight (KG) | |||

| 7/8-8 | 160 | 140 | 90 | 70 | 22 | 20 | 8.6 | 3.85 |

| 10-8 | 200 | 140 | 110 | 70 | 28 | 22 | 14.5 | 5.52 |

| 13-8 | 270 | 180 | 140 | 100 | 36 | 28 | 23.1 | 13 |

| 16-8 | 280 | 200 | 155 | 110 | 40 | 32 | 29 | 16 |

| 18/20-8 | 320 | 225 | 170 | 125 | 45 | 36 | 36.5 | 23.6 |

- CBX master link assembly

- Welding master link assembly

- Forging master link assembly

CBX master link assembly

Specifications WLL (T): 4.3, 6.5, 8.5, 11, 13, 17, 20, 27, 30, 40.

| CBX master link assembly breaking load (4XWLL) | ||||||||

| specification | Inside length | Inside width | diameter | WLL (T) | Weight (KG) | |||

| 4.3T | 135 | 100 | 75 | 60 | 18 | 16 | 4.3 | 1.83 |

| 6.5T | 150 | 120 | 90 | 70 | 22 | 16 | 6.5 | 2.65 |

| 8.5 | 170 | 120 | 95 | 70 | 25 | 20 | 8.5 | 4.1 |

| 11 | 200 | 120 | 120 | 70 | 28 | 20 | 11 | 5.1 |

| 13 | 200 | 135 | 120 | 75 | 30 | 22 | 13 | 6.1 |

| 17 | 250 | 135 | 150 | 75 | 36 | 25 | 17 | 9.6 |

| 20 | 250 | 180 | 150 | 100 | 38 | 28 | 20 | 9.8 |

| 27 | 280 | 200 | 170 | 120 | 45 | 32 | 27 | 16 |

| 30 | 300 | 200 | 200 | 120 | 45 | 36 | 30 | 17.5 |

| 40 | 300 | 180 | 200 | 100 | 50 | 38 | 40 | 21 |

Welding master link assembly

Specifications: 7 / 8-8, 10-8, 13-8, 16-8.

| Welding master link assembly breaking load (4XWLL) | ||||||||

| specification | Inside length | Inside width | diameter | WLL (T) | Weight (KG) | |||

| 7/8-8 | 160 | 60 | 90 | 35 | 20 | 13 | 4.6 | 1.7 |

| 10-8 | 190 | 80 | 100 | 40 | 25 | 16 | 7.8 | 3.3 |

| 13-8 | 240 | 90 | 140 | 50 | 32 | 22 | 14 | 6.8 |

| 16-8 | 280 | 100 | 140 | 60 | 40 | 28 | 24.8 | 12.5 |

Forging master link assembly

Specifications: M16,M18,S-10-8,S-13-8,S-16-8,S-20-8,S-22-8,S-26-8.

| Forging master link assembly breaking load (4XWLL) | ||||||||||

| specification | Inside length | Inside width | diameter | H | W | WLL (T) | Weight (KG) | |||

| M16 | 120 | 75 | 85 | 40 | 16 | 12 | 7 | 25 | 2.1 | 1.03 |

| M18 | 160 | 140 | 110 | 80 | 22 | 16 | 7 | 25 | 6.65 | 2.8 |

| S-10-8 | 190 | 160 | 110 | 90 | 26 | 20 | 11 | 35 | 9.4 | 4.8 |

| S-13-8 | 230 | 190 | 130 | 110 | 32 | 26 | 13 | 45 | 14.2 | 9.2 |

| S-16-8 | 270 | 230 | 150 | 130 | 38 | 30 | 16 | 45 | 22.3 | 14.7 |

| S-20-8 | 340 | 230 | 180 | 130 | 45 | 32 | 33.5 | 26.6 | ||

| S-22-8 | 350 | 275 | 190 | 150 | 50 | 38 | 40.8 | 39.0 | ||

| S-26-8 | 400 | 340 | 200 | 180 | 56 | 45 | 56.8 | 58.0 | ||

Packaging and delivery:

Usually packed in plastic bags, and then in export carton, high quality pallets; According to your requirements.

Delivery Detail: Usually 15-20 working days after receiving your advance payment.

About us:

1. Nearly 20 years experience in production

2. Owned factory, with superior quality and competitive price

3. Has a professional technical R & D team, integrating R & D, production and sales

4. The product has passed the environmental management system certification

5. ODM, OEM service is available

Company contact details:

Weifang First Rigging Co., Ltd.

Add: South Development Zone, Changle County, Weifang City, Shandong Province

Tel: +86-13173150811

Tel: +86-536-8266033

Fax: +86-536-6732909

Email: freddie@firstrigging.com